Rubber Gaskets FAQs

It may sound a little daunting, but this simply creates a standard way to determine the compressibility capabilities of the gasket. The three categories are soft, medium, and firm.

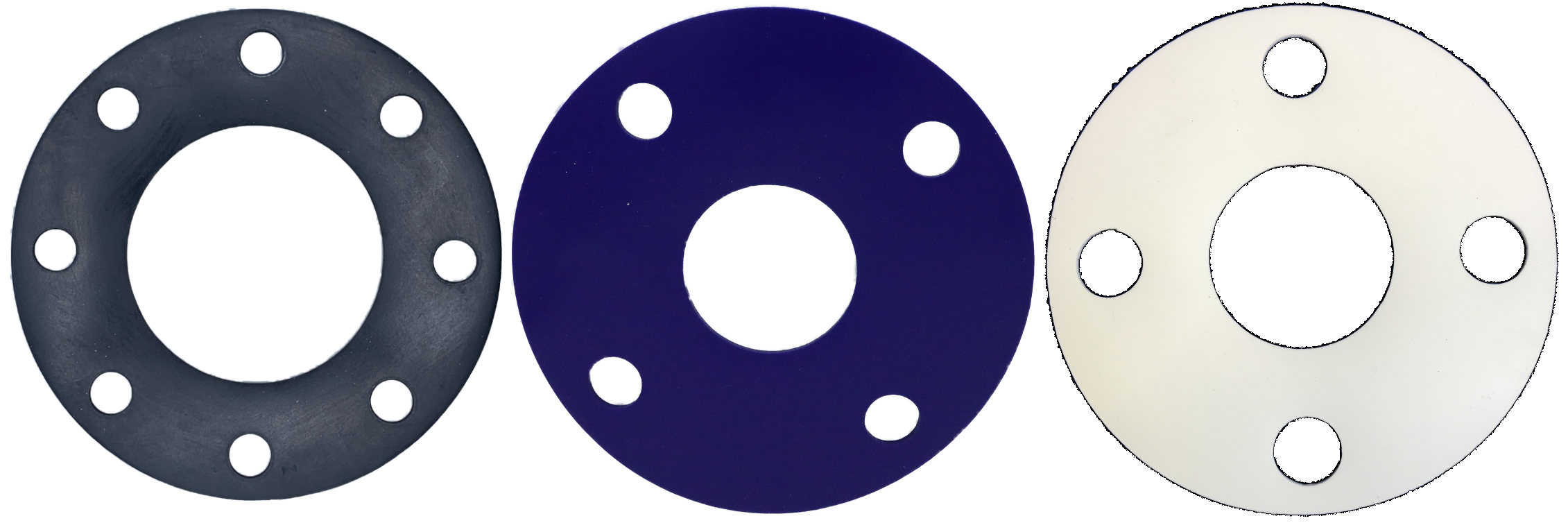

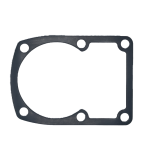

Gaskets can be manufactured in a range of configurations with different combinations relating to materials, dimensions, and other key attributes. Here at Munsch & Co, our manufacturing equipment offers a total of over 15,000 cutting forms, meaning you can find the perfect match for your intended application.

While a homemade gasket out of flat cardboard may work for some simple home DIY projects, you should always use professionally manufactured gaskets for cars or industrial use. This is because they are carefully designed to deliver a watertight seal and withstand the outside elements of temperature and pressure. Besides, they’re not expensive.

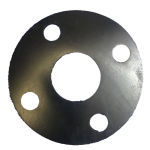

When the gasket is designed to seal oil in a car engine, storage tank, or industrial machine, nitrile is the most effective material type. They are cut from a larger metal sheet. Neoprene gaskets are another popular option thanks to their economical attributes.

Several gaskets may be deemed suitable for food production equipment, but they must meet MHRA regulations. Nitrile, silicone, neoprene, EPDM and natural rubber are the most common choices as they are non-toxic, flavourless, odourless, and hypoallergenic. They operate efficiently at a wide range of temperatures and prevent bacteria growth.

Like any moving part, gaskets do encounter wear and tear. But they are very durable. A gasket’s lifespan is influenced by several factors, including its functional workload and frequency of use. When you choose a high-quality product that matches the intended use, it should last for anywhere from 5 to 20 years.