- Home

- »

- Products

- »

- Gaskets

- »

- PTFE Gaskets & Seals

- »

- Gylon Gaskets

Gylon®

Gaskets and seals

Gylon®

Gaskets and seals

Table of Contents

As an Approved Distributor of Garlock materials, our range of Gylon® gaskets & sheeting is one of the most comprehensive in the UK.

We carry practically all styles of Gylon® in a wide range of thicknesses.

Our Gylon® gaskets and sheet are supplied to industries throughout the UK, Europe and even as far as Australia.

The unique properties of Garlock’s Gylon® range make it the preferred choice of material for a broad spectrum of industries, from chemical manufacturing, food processing, and pharmaceutical applications.

Garlock is the global leader in PTFE based materials and our solutions are customised to your exact specifications, meaning that they comply with the most stringent regulations.

Simply give us a call or fill in the enquiry form below and one of our experts will give you all the advice and guidance on our Gylon® range.

Gylon Gaskets Enquiry

What is Gylon®?

- Gylon® is a range of restructured PTFE gasketing materials which have excellent chemical resistance, and significantly reduce creep relaxation problems often experienced with conventional PTFE.

- Garlock’s Gylon® gasketing is a family of harsh service PTFE gasketing materials manufactured using a proprietary process that imparts unique physical properties, that are not attainable through conventional manufacturing methods.

What are the advantages of Gylon®?

- Gylon’s state-of-the-art manufacturing process reorients the PTFE and fillers in a way that increases the material’s tensile properties and decreases the creep relaxation problems that commonly afflict PTFE products.

- In addition, the mixing process creates a homogenous material with consistent, superior physical properties that, unlike inferior skived PTFE sheet gaskets, do not fluctuate from one side of the sheet to another.

- Plus, Garlock’s patented thermal bonding process allows us to fabricate a Gylon gasket to nearly any size.

What are Gylon's® benefits?

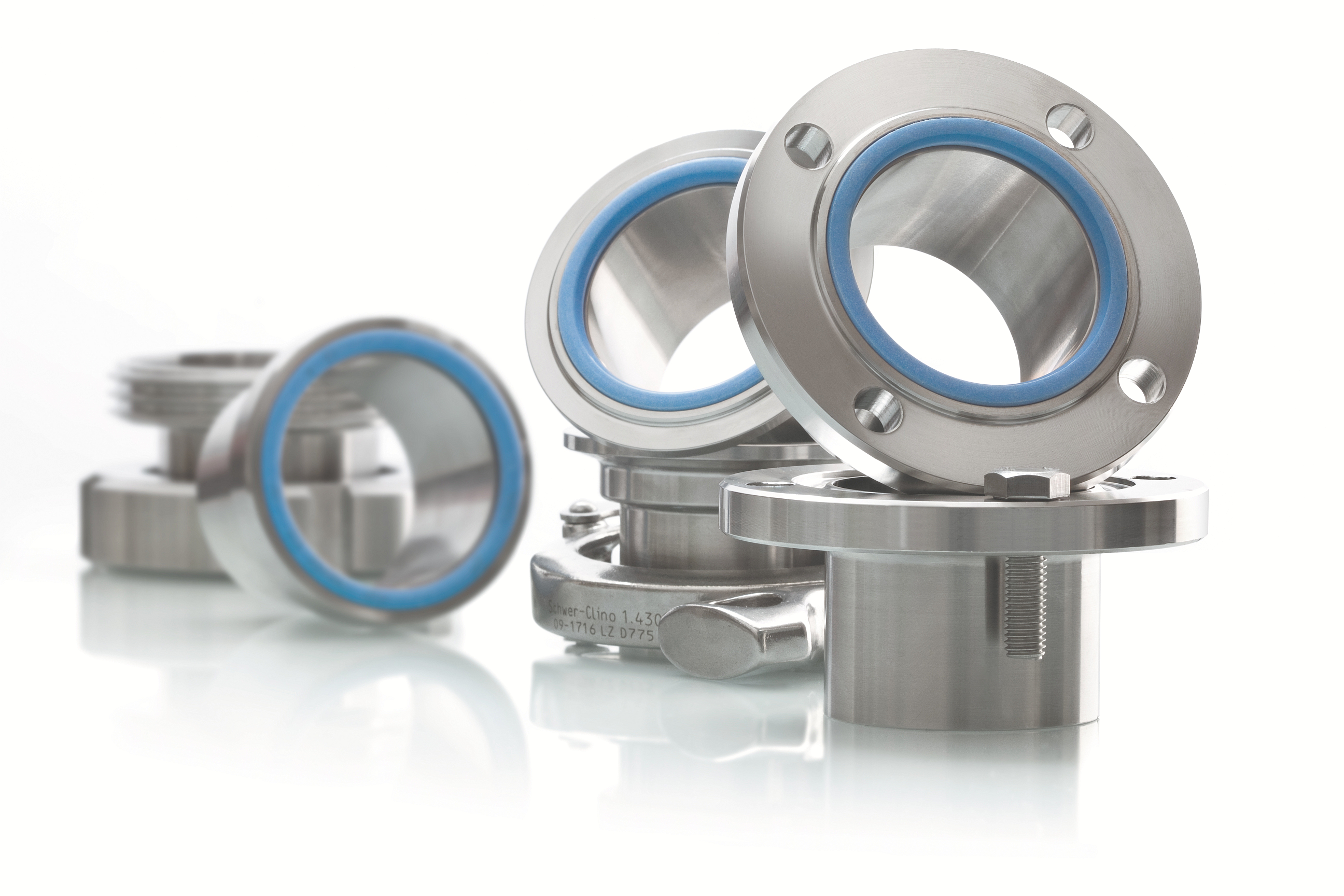

- Designed for severe chemical service, Gylon® gaskets are color-coded for easy identification.

- They provide superior sealability to reduce process and media loss and fugitive emissions.

- Creep and cold flow characteristics are also reduced in temperatures ranging from -268 to +260°C

- They can operate in a pressure range of between 55 and 82 BAR.

Why buy Gylon® from us?

- We stock and convert Gylon gaskets and seals from one of the largest stocks held in the UK.

- Our experience of the Gylon range of materials is vast and our aggressive centreing out pricing policy means you can be rest assured you will get the highest quality products at attractive prices.

- Plus, all our range is supplied in accordance with our ISO9001:2015 quality system, which means you get the right product, at the right price, at the right time.

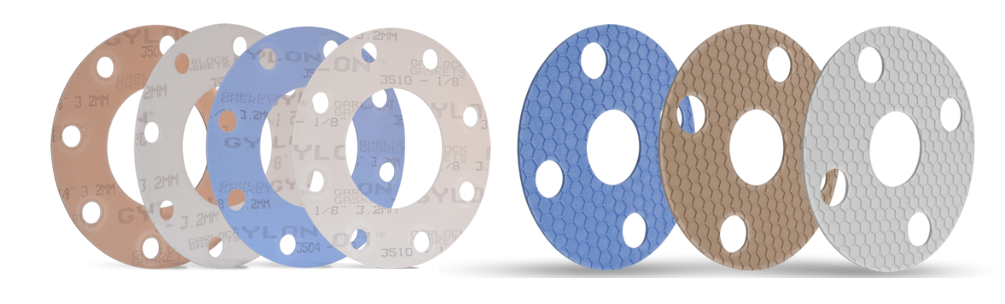

Gylon® Styles

For additional information, click on the image or the hyperlink.

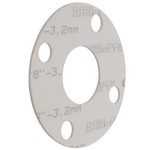

Meeting FDA, ABS and USDA specifications, this Fawn Gylon with Silica can be used with Strong acids (except hydrofluoric), steam, solvents, hydrocarbons, chlorine and cryogenics.

Manufactured in Europe, this grade is suitable for use with Strong acids (except hydrofluoric), steam, solvents, hydrocarbons, chlorine and cryogenics. It meets BAM, FDA, KTW, and TA-Luft specifications.

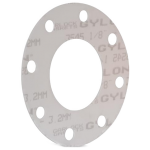

Arguably the best known material in the Gylon range, this PTFE with Aluminosilicate microspheres meets FDA specifications and is suitable for use with acids, some caustics, refrigerants and cryogenics.

This FDA compliant, PTFE gasketing material is designed to compress and conform to irregular or damaged surface. This makes it suitable for flanges that generate lower stresses, such as lined flanges and equipment.

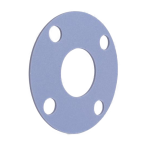

We also offer Garlocks’ patented Gylon® thermal bonding process which allows us to manufacture and supply very large gaskets without dovetailed joints, for excellent chemical resistance and sealing performance. Available on 3501, 3504 and 3510.

Special Order Range

The following products complement the main Gylon® range and are available to special order subject to minimum order quantities.

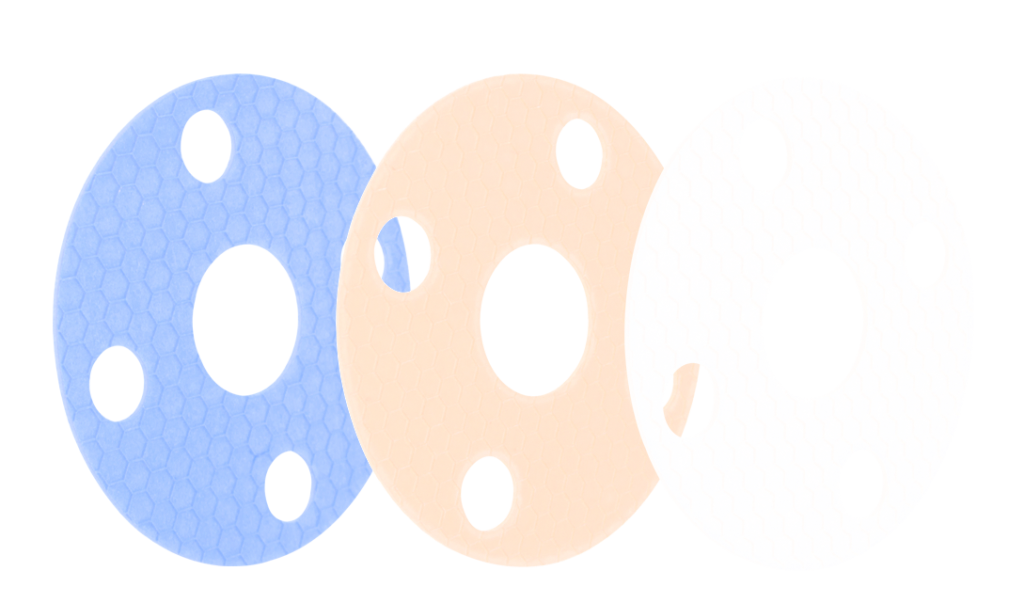

Introducing the Gylon Epix® Range of Materials - PTFE Gaskets' Next Generation

is a recently developed family of PTFE gaskets. It is produced using a patented, profiled surface based on our proven Fawn, Off-White, and Blue GYLON® to create highly conformable materials for optimum sealing performance.

GYLON EPIX® will provide superior functional performance by combining the traditional attributes of GYLON® with an innovative surface design. It offers a wider range of applications than traditional PTFE gaskets, that are used in worn and pitted flanges. Additionally, GYLON EPIX® provides the tight sealing and load retention properties of 1/16” (1.6mm) and the conformability of 1/8” (3.2mm).

The hexagonal profile provides improved compressibility and recovery, and the profiled surface reduces the contact area during initial compression, to concentrate the compressive force of the flange, for improved sealing.

Designed for increased compressibility, GYLON EPIX® improves performance in misaligned flanges. The consolidation of two thicknesses to one reduces the need to stock multiple thicknesses. Therefore, with an improved design, color-coded materials, and single thickness, GYLON EPIX® makes sealing easier.

We are happy to advise on any application, but final responsibility lies with the customer.

Gylon® is a registered name of Garlock, an Enpro (NYSE: NPO) Company.