NON-ASBESTOS

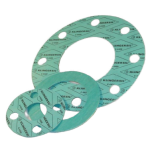

Gaskets and seals

NON-ASBESTOS

Gaskets and seals

Table of Contents

If your application needs resistance to high temperatures, (Up to 400° C) or high pressures, (Up to 140 Bar), we supply Non-Asbestos gaskets in our full range of materials.

Asbestos gaskets were used in heavy industry, engines and pipelines, until public awareness of diseases linked to asbestos meant that manufacturers had to develop alternative materials for gaskets. The replacement materials they developed are made by compressing fibres, (aramid, inorganic or graphite) with a rubber binder, which is a lot safer than, the now banned, asbestos. They can also be referred to as fibre, CNAF or NAF gaskets.

The rubber binder is usually Nitrile, but there are variations if you need a different binder, like EPDM or SBR, for instance.

We make Non-Asbestos gaskets from our range of materials produced by the world’s leading sheeting manufacturers, including Garlock, Flexitallic, Klinger and Reinz.

Unlike CAF (Compressed Asbestos Fibre), there are many different grades of Non-Asbestos gaskets. With our knowledge and familiarity with the materials, we can help you select the right grade for your application.

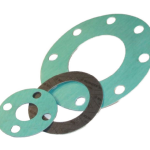

Our team are experienced at producing all types of Asbestos free gaskets in our gasket shop. We produce standard table gaskets daily, however if you need a bespoke seal making, we will work with your drawings or samples.

We often utilise our two, oscillating knife CAD/CAM cutting tables to produce the gaskets, because we can “Nest” a series of gaskets to achieve the best yield from the material.

Simply give us a call or fill in the enquiry form below and one of our experts will give you all the advice and guidance to meet your rubber gasket requirements.

Non-Asbestos Gaskets Enquiry Form

All the Non-Asbestos gaskets that we manufacture are produced in accordance to our ISO9001:2015 quality standards.

Below, we will give an overview on each grade’s main features.

Temperature range, pressures and chemical resistance vary between the grades, but by clicking on the link, you can download a more comprehensive data sheet.

Styles of Non-Asbestos Gaskets

Styles of Non-Asbestos Gaskets

Click on the links below to download a data sheet on the different grades.

Garlock Materials

Comprising of synthetic fibres with a proprietary rubber binder. This unique style is suitable for use with water, oils and fuels and has a temperature range of -73 to +205° C.

Aramid fibres with a nitrile rubber binder, this BS7531 Grade Y material is ideal in applications involving water, aliphatic hydrocarbons, oils

and gasoline, at temperatures between -73 to +205° C.

Aramid fibres with a SBR binder means this style is appropriate for use with water, saturated steam & inert gases. It’s operating temperature range is wide at -73 to +205° C with a maximum short term of +371° C.

This grade consists of aramid fibres with a neoprene binder. Typical applications are water, saturated steam, refrigerants, oils and fuels. It’s temperature range is -73 to +205° C.

Aramid fibres with a SBR binder make Bluegard® Style 3400 suitable for use with water, saturated steam and inert gases. Its operating temperature range is -73 to +205° C.

Water, saturated steam, and mild chemicals are typical applications that this grade of aramid fibres with an EPDM binder is used for. It’s operating temperature range is broad at -73 to +205° C with a maximum short term of +371° C.

This ABS Fire-Safe Type Approved grade comprises of inorganic fibres with a Nitrile binder. Its temperature range is -73 to +288° C. Applications include saturated steam, most refrigerants, water, oils, gasoline & aliphatic hydrocarbons

Carbon Fibres with a NBR binder make this suitable for saturated steam, water, oils, inert gases, aliphatic hydrocarbons & fuel. The carbon fibres mean it has a wide temperature range of -75 to +343° C. It is also ABS Fire-Safe Type Approved.

Produced using an environmentally friendly solvent-free process and combining a unique formulation with a patent-pending fibre core. THERMa-PUR™ is capable of constantly operating at +1000° C. It is resistant to a broad range of chemicals.

Carbon Fibres with a SBR binder in this high temperature grade mean it can operate at up to +288° C. It is typically used with water, saturated steam, and inert gases.

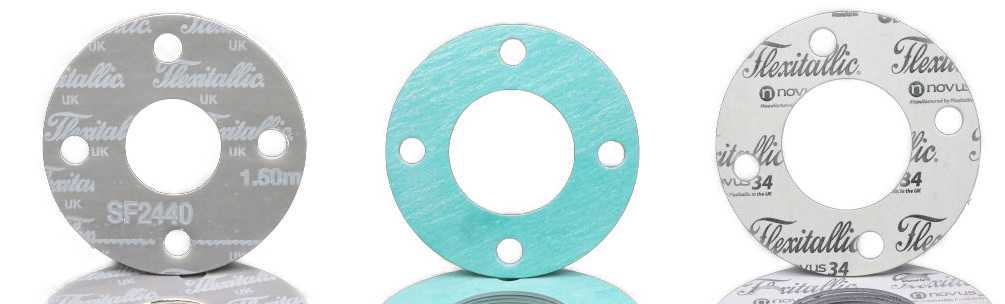

Flexitallic Range of Non-Asbestos Gaskets

This BS7531 Grade Y, and WRAS approved grade, is a good quality compressed sheet material based on a blend of aramid and inorganic fibres with a nitrile binder. Typical service includes steam, oils and fuels, up to +225° C.

This WRAS approved BS7531 Grade X material is based on a blend of aramid/ inorganic fibres and special additives, with high quality nitrile rubber binder system making it suitable for use with oils, solvents, and gases including oxygen up to +250° C.

Manufactured from virgin fibres and recycled material, with a nitrile rubber binder, means this cost effective Non-Asbestos is suitable for medium duty applications, like oils, solvents, gases, water, and low pressure steam at temperatures up to +150° C.

This WRAS, BAM and Grade X approved grade combines a high percentage of graphite, reinforced with aramid fibres and a rubber binder. Suitable for many applications, including oils, solvents and gases, including oxygen at temperatures up to +250° C.

Manufactured for us in the UK, by Flexitallic and based on a blend of aramid and inorganic fibre with a nitrile binder. Greeneseal© is a medium quality, cost effective non-asbestos gasket material. Suitable up to +150° C. See our data sheet for more details.

Klinger Range of Non-Asbestos Gaskets

Complying with BS7531 Grade Y, this gasket material bound with NBR is based on a combination of synthetic high-tech fibres. It displays good chemical resistance against water and oil and has low gas leakage. Suitable up to +150° C continuous.

Made with Aramid fibres bonded with NBR makes this grade resistant to many chemicals including oils, steam, gases, fuels, alcohols, organic and inorganic acids. It has a temperature range up to +150° C and +400° C in low pressure applications.

Optimum combination of synthetic and

glass fibres bonded with NBR makes this material resistant to steam and water at high temperatures (+250 – +400° C) as well as to oils and hydrocarbons.

C-4430 meets the requirements of BS 7531 Grade X, is WRAS approved for use with potable water and is also fire-safe. C-4430 also has TA-Luft (Clean Air) approval.

C-4500 is a premium material based on carbon fibre with NBR binder. It is designed for use with higher pressures and temperatures than the majority of calendared materials. Carbon fibres increases resistance to temperature related aging, and to attack when used in alkaline services.

C-4500 is fire-safe.

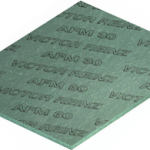

Reinz Materials

AFM-30 consists of aramid fibres and other asbestos substitutes bound together with high grade elastomers. Seals can be used continuously at +250° C. It is resistant to engine, transmission, hydraulic, and refrigerating oils, together with fuels.

A blend of aramid fibres, inorganic fillers and

other high temperature resistant substances. It complies with various standards including WRAS and FDA, It can be used with many different medias. (See the data sheet) up to +250° C continuous.

The temperature ranges of the above grades are a guide and it is important that you check the full data sheet, or discuss your application with one of our experienced team, as you may be restricted depending on the pressure and media.

We are happy to advise on any application, but final responsibility lies with the customer.