What is EPDM Rubber?

Table of Contents

What is EPDM Rubber?

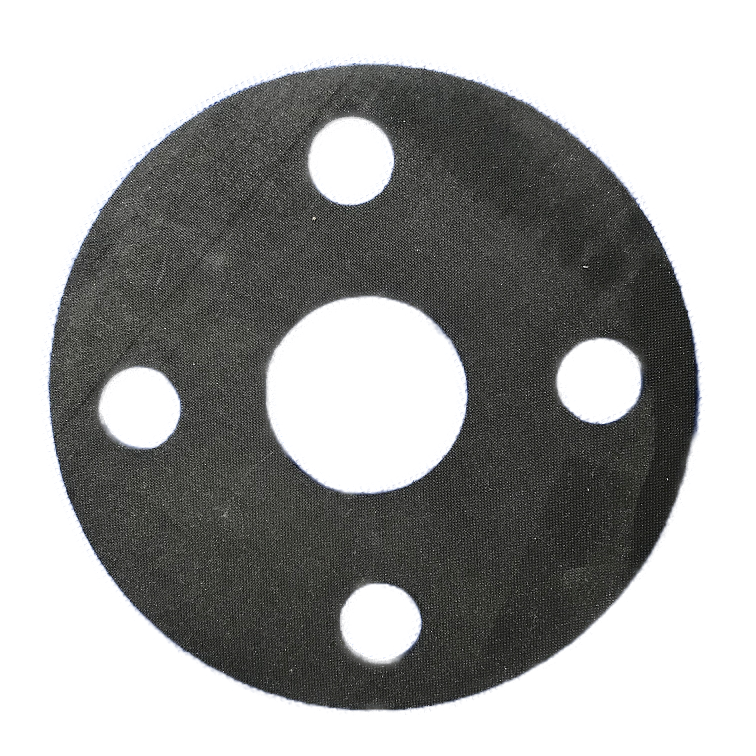

EPDM is the shortened form of ethylene propylene diene monomer, which is a high density synthetic rubber made up of monomers of the same name. Products made with EPDM have a long term lifespan and the products also rarely need replacement parts, which is perfect for businesses looking to invest because it saves money in the long term. Understanding what EPDM rubber is is vital, so let’s look at what it is, what it does and where it’s used.

Benefits of EPDM Rubber

Did you know that EPDM is durable? No, extremely durable! It’s actually known for being one of the weather resistant materials out there in the synthetic elastomer category. EPDM has some of the best resistance to weathering, ozone, UV and aging and it can exhibit the best electrical insulation, too. EPDM rubber can also offer a good compression set and low temperature properties, too. It’s resistant to a range of fluids including water and antifreeze, and if there are any water based chemicals and vegetable based hydraulic fluids, it’s resistant to that also. Liquid fertilizers and brake fluids are also on the list of materials that EPDM rubber is resistant to, too.

Where is EPDM used?

Did you know that EPDM is most commonly used in specialty applications? It’s one of the fastest growing synthetic rubbers that can also be used for general purpose and the biggest EPDM market is the automotive industry. This is generally because it has excellent vibration absorption, with high heat and weather resistance, too. EPDM is an exceptionally flexible rubber, too, and it’s usually seen in applications like braking systems, rub strips, weather stripping and window and door seals.

It’s important to note that EPDM is not the rubber that’s recommended if there is gas, oil or hydrocarbons present. There is a limited compression set resistance and won’t adhere to fabrics and metals in these cases.

EPDM: Physical characteristics

Elastomers such as EPDM have physical characteristics in tensile strength, elongation and compression set. It also has an ASTM D2000, which is the code for American Society for Testing and Materials. It’s these who established ASTM D2000 and this is the standard classification for rubber products in automotive applications. This isn’t just about the automotive industry, either. You can find it in medical applications, construction and in aerospace, too. A durometer is the standard way that a rubber or plastic material is measured for hardness, and this is used with a scale between 0 and 100 and the higher this number measures, the harder the compound is. The standard for EPDM is 70 Shore A. This means anything less is softer and anything more is harder, and the usual ASTM D2000 specification is 70, with the number ranging from 30 to 90 Shore A.

The usual ASTM D2000 specification for EPDM is 2031 psi, with a typical value of 500-2500 psi. This refers to the tensile strength of the resistance of a material to stretch. At breaking point, this is expressed as pounds per inch. The elongation of EPDM is 600% before it gets to breaking point. It’s reflective of the size of the product at the space it breaks vs its starting point. There’s no specific ASTM D2000 requirement for elongation, however, which is why it has a fairly wide margin for error.

The compression set – the amount of deformation over time that’s permanent when a material is compressed at a specific temperature and time. EPDM has an ASTM D2000 requirement using a compression set of 22 hours at 125x, with a permanent set of 25%. This is the percentage of the original compression that’s not recovered.

Where to buy custom EPDM

The demand and supply of EPDM has been disrupted by COVID-19, but you can still buy EPDM products. As a domestic supplier, EPDM.co.uk are happy to offer EPDM products to those looking for it and with 50 years of experience in the industrial rubber and sealing sector, we have more than enough recognition as a stockist of rubber and sponge with thicknesses up to 50mm. We offer our products quickly and over the years, we’ve grown into stocking a wide range of rubber from manufacturers like Hatcham, Maclellan, Dunlop and Gates. Sadly, 3 of these manufacturers are no longer supplying rubber sheeting, so we now supply materials from leading manufacturers like Trelleborg and Semperit.

The company has changed over the years, including expansion of the workforce, new machinery and more. What hasn’t changed is exceptional service and delivery by our team.

Contact us today and get the help you need for your EPDM rubber materials.

Related articles

If you need any help or advice simply give us a call or fill in the enquiry form and one of our technical team will help you out.