How do I know which gaskets I need?

Skip to

Firstly, what is a Gasket?

A gasket is a material that’s compressible and used to create a new seal between two stationary faces. These are common in pipe flanges and you’ll need a gasket to create that seal. It’s so difficult to achieve a smooth face on metalwork that is completely smooth without one. Without a gasket, you also risk the joint corroding over time, and to be effective, your gasket has to be tested with sufficient force for it to make the right seal.

The right pressure has to be applied to retain that seal and the right choice and fit is essential for automotive projects and other industry options. For example, a gasket is vital for appliances and engines as well as making the seal with industry machinery.

As a high quality manufacturer of gaskets, we only use the finest materials and the latest precision techniques to ensure that your gaskets are the right ones. Talking to one of our experts today could help you achieve what you need and get you the gaskets that make sense for your operation.

Gasket Applications

There are different gaskets for different applications and either way, you need to understand that the materials used have to withstand the daily wear and tear. There are some critical factors that matter when choosing your gasket, including resistance to corrosion and temperature.

At EPDM, we can ensure that you get the best gasket selection and solution for your needs. If there are any errors made in the materials, gasket type or configuration (we’ll come to this later), you will end up with contamination later on. Our team can help you to bypass this and choose only the best. Let us save you time and money from the start.

Things to Consider in Selecting The Right Gasket

It’s easy to overlook the gasket you need so the considerations below should be made when you are searching for the right one.

The right manufacturer

There are very strict regulations in the manufacturing process for creating gaskets. These strict regulations can ensure that you get that reliable gasket you need.

Established in 1972, Munsch & Co has 50 years’ experience in the Industrial Rubber and Sealing Sector.

Configuration details

Seals and gaskets can both lose their longevity over time if the configuration details are not on hand to help the process. Having the configuration details on hand will help the process, and some of the conditions that you have to address with seals and gaskets include:

- Temperature

- Pressure

- Stresses

- Opposing forces

- Stresses

- Corrosion

With the right experts helping you to choose which gaskets you need, you can avoid gasket failure due to wear and tear later on.

The right material

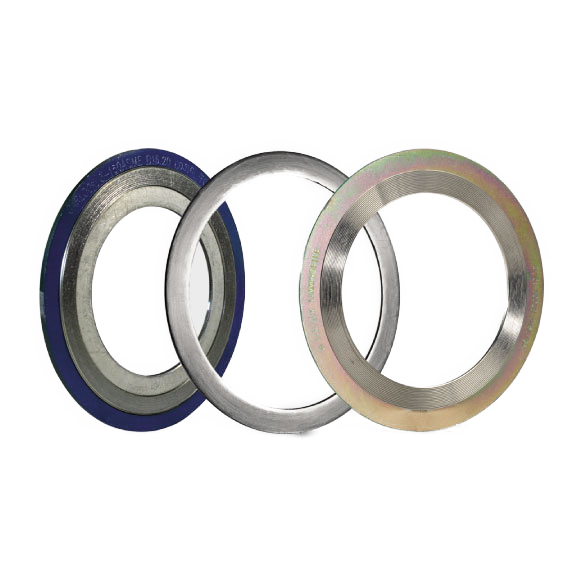

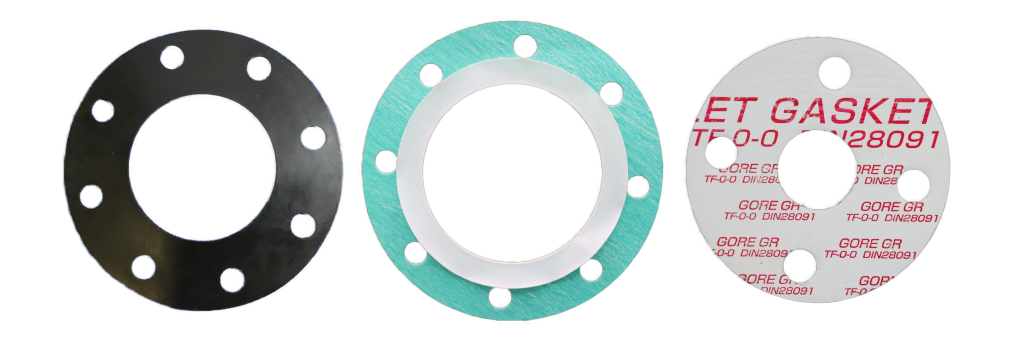

Did you know that there are different materials used in the manufacturing of gaskets? The type and use vary but this depends on the construction. Metallic gaskets, for example, are designed to withstand extreme pressure. They are able to be manufactured to bespoke specification and they are able to withstand very high (or low) temperatures. If metallic gaskets are exposed to chemicals, they can withstand that, too!

Another material to consider are the semi-metallic gaskets. These are more versatile, made with a flexible core that is covered in metal. Used mostly in the gas industry for pumps or gas mains, the material is the perfect balance for heat exchange as well as high fluid. There are also non-metallic gaskets that are made from materials like rubber, silicone and carbon fibre.

Related articles

If you need any help or advice simply give us a call or fill in the enquiry form and one of our technical team will help you out.